INSPECTION & TESTING SAFETY EXPLAINED

INSPECTION AND TESTING SAFETY EXPLAINED

Inspection and testing of electrical installations is an important and necessary activity to protect the safety of the users of the installation against fire, shock and burns and damage to property as set out in the IET Wiring Regulations (BS 7671: 2018 Amendment 2:2022) Chapter 13 Fundamental Principles.

The Wiring Regulations in Chapter 64 Regulation 641.1 requires new installations, alterations to additions to existing installations to be, during erection and on completion be inspected and tested to verify, so far as reasonably practicable, that the requirements of BS 7671 have been met.

For a new installation, or an addition or alteration to an existing installation, requires three activities to be undertaken in sequence. They are to inspect the installation, which shall normally be done with the installation disconnected from the supply, carry out the tests in the appropriate sequence defined in Chapter 64 and to certificate the results of the inspection and testing. The dead testing of the installation has to precede the live testing to ensure the installation can be energised safely for the first time to perform live testing.

For Periodic Inspection and Testing, the Wiring Regulations do not define any particular tests or a sequence of testing only that the inspection is supplemented by appropriate tests and measurements set out in Chapter 64. The objective of a Periodic Inspection and Test is set out in Regulation 651.1. This is to, to determine so far as practicable, whether the installation is in a satisfactory condition for continued service. So, the major activity is a thorough inspection followed by testing. The issue of an Electrical Installation Condition Report together with schedules on inspection and testing results is a requirement.

The first activity is to ensure that the person carrying out the testing is qualified and competent to carry out the required inspection and tests and has experience of the particular type of installation to be inspected. A Statutory Requirement of Regulation 16 of the Electricity at Work Regulations 1989 (EAWR) requires a person carrying out electrical work to be competent.

Before starting work on site, a risk assessment and method statement should be produced by a person competent to carry out the task in compliance with the Management of Health and Safety at Work Regulations 1999. The results of this process then need to be communicated to the person carrying out the inspection and testing and to any person assisting them. When considering the use of PPE rubber soled shoes in good repair and eye protection should be a minimum requirement.

A fundamental task for anyone carrying out work on an electrical installation is to understand the requirement for safe isolation as required by Regulations 12,13 and 14 of the EAWR.

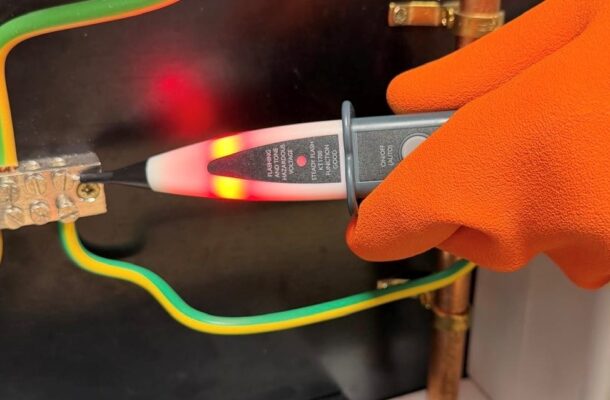

To carry out safe isolation the Inspector will need a 2-pole voltage tester, a non-contact voltage indicator, a clamp meter, a proving unit and a lock off kit.

The Kewtech KT5 2-pole voltage tester will detect a live voltage with one probe if a 2-pole test is carried out and a protective conductor or a neutral is not present unlike some 2 pole testers that need a potential difference between the probes to detect the presence of a live conductor. It will also measure voltages up to 1000V AC and 1500V DC.

The KT5 has a non-contact voltage detection function which is useful for proving the outside of a distribution board, feed pillar or street cabinet is dead before touching it.

The KT5 also benefits from a current testing fork that can be used to detect current flowing in protective conductors due to PEN conductor faults.

Kewtech have a range of lock off kits available for a wide range of installation types. Kewtech also supply a range of 5 different isolation kits. The Kewtech Kewstick Duo complements the 2-pole tester and is a useful tool for continually proving dead at regular intervals when working on an installation after safe isolation. All Kewtech single and 2 pole testers have fixed thin tips so to always comply with HSE GS38 requirements.

Left: Kewtech safe isolation kit. Right: Permanent GS 38 probe tips.

To carry out installation tests the Inspector can use a range of single function or dual function instruments or more commonly a Multifunction Tester (MFT).

Regulation 634.1 of Wiring Regulations makes a requirement to use instruments complying with the relevant parts of BS EN 61557. The instrument should also be selected for working on LV installations to meet the Cat III requirement of BS EN 61010-1 which is to have a voltage rating of 300-600V with a voltage impulse rating of 4kV. The Kewtech KT66DL meets, and exceeds these requirements, and has functionality to perform a full range of installation tests including continuity, insulation resistance, low current and high current loop impedance tests both 2 wire and 3 wire, RCD testing, voltage measurement, earth resistance and phase rotation tests. The KT66DL can perform high current loop tests at 25A for more accurate readings of PFC/PSC when close to a supply transformer. The instrument is ergonomically designed and intuitive to use and is fitted with a neck strap. It is recommended that Inspectors use the neck strap at all times to leave both hand free and to prevent accidental damage to the instrument if dropped.

Kewtech KT66DL MFT with a range of GS 38 leads, probes and crocodile clips with HBC ceramic fuses. Image includes optional extra ACC070 fused croc clips and probes.

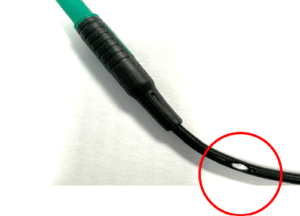

The KT66DL is complemented by a range of test leads, probes and crocodile clips. It is important that the leads, probes and crocodile clips comply with Health and Safety Guidance Document GS 38. The test clips should ideally have parallel jaws with a good “bite” to them to reduce testing errors. When working live on high current supplies it is recommended for safety to use fused probes containing HBC ceramic fuses to reduce the risk of arc flash in the event of an accidental short circuit. Kewtech supply a wide range GS 38 compliant leads, probes and crocodile clips suitable for both live and dead testing. Kewtech leads are double insulated and have a different colour inner insulation layer to indicate damage to the outer insulation sheath.

A Kewtech lead indicating damage with the double insulation bi-colour inner insulation

Before using any test equipment or test leads, they should be inspected for damage to ensure they are in good working order and the instrument has charged batteries. Regular confidence testing of the instrument and leads is recommended using a range of known resistances for continuity and insulation resistance ranges and a designated socket for loop impedance and RCD testing. The Kewtech FC2000 Check box is a convenient way of testing for on-going accuracy of continuity, insulation resistance, loop impedance and RCD tests. The results of the tests and the date should be recorded to identify any deterioration of the instrument accuracy and leads over a period of time. Confidence testing is not a substitute for formal calibration testing and it is recommended that this is undertake yearly and a calibration certificate obtained. Kewtech provides a calibration service for all makes of test instruments in an accredited laboratory.

A Kewtech FC2000 undergoing a confidence test of the KT66DL prior to testing.