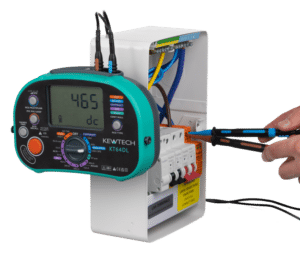

The Kewtech SPD test simulates a voltage surge, allowing you to check the SPD’s ability to clamp and divert excessive voltage. This is a critical test to verify that the SPD can handle potential surges without damaging the connected equipment.

Kewtech’s SPD test also assesses the SPD’s energy absorption and discharge capacity. This ensures that the SPD can safely handle repeated surge events over time without degrading, guaranteeing long-term protection for your electrical systems.

As the test produces a surge of up to 1000V with a maximum of 1mA, the energy dissipated across the SPD is less than 1 Watt, which does not harm the SPD’s life. The test then performs a calculation to provide you with your DC and AC breakdown voltage values.

Kewtech models that can perform this SPD test:

KT66DL Advanced Multifunction Tester

KT300DL Single Function Insulation / Continuity tester.

For more info on why and how to test SPDs click here…

For more information on safe isolation click here…

Yes. Both the KEWEVA and KEWEVSE uses 4mm lead connections so are compatible with all MFTs using standard 4mm connections. The KEWEVSE also has a 13A socket.

However, in the case of testing EV charge points, the adapter’s capabilities are limited by the functionality of the MFT being used. For example, you can use the adapter to help you carry out a 6mA RCD test, however, only if your MFT has the capacity to do so like the Kewtech KT66DL and KT64DL do.

The KEWEVA and KEWEVSE can be used to test a 3 phase charge point by connecting the distribution board leads on the MFT to the 4mm connections on the adapter.

The old version KT63 can test type AC and ACS RCDs.

The new version KT63DL can also test A type RCDs as well as having a 10mA RCD test.

Good news…we can upgrade your KT63 to the new version KT63DL which includes both a hardware and software upgrade as well as a new printed circuit board and calibration.

To book your KT63 in for an upgrade or to find out more, simply call 0345 646 1404 and select option 2 for our repair and calibration service.

The pad is a touch pad that references you to earth when connected to a live circuit. If the voltage is greater than the UL setting, which is 25V for animals and 50V for humans, then the tester will show UC greater than UL and will halt the test.

We recommend an annual calibration, however, there is no hard and fast rule. You are responsible for ‘knowing that your instruments are reading correctly at all times’, so if your instruments are used aggressively, say in an instrument pool and are taken out daily with little accountability, then you may want to have them tested more frequently.

If, on the other hand, if you personally look after your instruments, regularly against a check box such as our FC2000 and see no drift, you may feel that is OK to extend the calibration period.

Just by removing the Null and re-Nulling may be a simple solution, see ‘The importance of test lead nulling’.

Then for further checks test the leads and continuity circuit. Set the instrument to continuity and with the NULL ‘OFF’, loop each test lead in turn by putting one end in the brown ‘Live’ port and the other end into the green ‘Protective Earth’ port*. Press the test button to make a measurement, the resistance of each lead should measure substantially the same. This not only checks the lead but also the internal circuits/fuse.

Should it be one of the rare occasions where the fuse is blown, replace the user-replaceable fuse in the battery department.

If the instrument is a KT65DL or KT66DL there is a spare replacement fuse located in the battery compartment.

Please note the replacement has to be a 500mA F 600V ceramic fuse.

*For the KT63DL these two ports are marked ‘+’ and ‘–‘

Try a ramp test as it could be the RCD you are testing rather than the tester.

Check the type of RCD you are testing. Is it an A or AC type? Have you selected the correct rating, ie 30mA?

If you are still having problems please give us a call on 0345 646 1404 and select option 4.

In this video, the eFIXX team highlight the challenges of testing electrical installations with integrated electronics! From USB charging sockets to EV chargers, these permanently connected loads can complicate electrical insulation tests.

Firstly, check you test leads and ensure the fuse in the battery compartment is sat tight in the holder.

If the issue remains, you could have tiny debris particles on the selector pad of the PCB which are affecting internal components and your meter may require a service.

To book your tester in for a service please complete the calibration and service form which can be found here.

- From the off position. Hold down the RCD select button marked x1/2 x1 x5 and the continuity null key at the same time and turn the dial to one of the battery symbols. If the meter shows ACC OFF release the buttons and turn off the meter. To switch the ACC back on.

- Hold down the RCD select button marked x1/2 x1 x5 and the continuity null key at the same time and turn the dial to one of the battery symbols.

- If the meter shows ACC ON release the buttons and turn off the meter.

- It is better to have the ACC ON however on occasions the protection can be oversensitive, and you would therefore need to turn the ACC OFF.

This is good practice. Carry it out before you start your days testing.

- Select continuity.

- Press the CONT NULL key with leads separated.

- Screen displays >5.00 NULL disappears.

- This has cleared the null memory.

Re null

- Crocodile clips should be connected bottom jaw to bottom jaw.

- Press CONT NULL. Value shows. Example 0.12 Ω then press the large orange test button.

- If the continuity values are varying, please carry out the following.

- Remove fuse and squeeze the fuse contacts slightly to ensure the fuse is seated correctly.

- Clear the null memory and link one lead between the brown/red and blue/black ports. Press the CONT NULL button only and look for a constant value.

Firstly check that you have working batteries in your tester and that they haven’t gone flat.

Our voltage testers will show voltage even without batteries for added safety, however they will require batteries to show continuity. Flat batteries are the most common fault for voltage indicators not showing continuity.

Note: To check continuity, ensure batteries are good. Place tips together and manipulate the test leads especially around the tapered end. If you wrap your leads very tightly and leave them in your bag or toolbox for any length of time, the copper may harden and become brittle.

Cory explains the importance and theory of earthing systems, this is often skipped over in the design phase!

Yes, all Kewtech Pat testers comply with the 5th edition.

PAT testing or more accurately Electrical Equipment testing is so important as more people get injured through faulty equipment than they do with problems with the fixed wiring of an installation. The key changes between COP 4 & 5 have been the emphasis on the use of 250 V insulation testing where sensitive electronic equipment is being tested and a change in the allowable limits, these have been relaxed.

All our testers have the 250 V insulation range and the latest limits as pass and fails. The Code also describes two levels of competence to conduct testing.

The EZYPAT is perfect for the level 1 operator as it has green and red, go / no go indication. The EZYPAT Plus and the SMARTPAT are ideal partners to level 2 operators and offers run / leakage testing and the SMARTPAT offers fast test results downloading with the accompanying app.

Yes! The KEWPAT app is designed to work manually with all our PAT testers. Simply download it today for FREE onto your iOS or Android device and see how easy it is to use.

The KEWPAT app enables fast documentation including appliance risk assessment, visual inspection, record documentation and covers your obligation to hold a product register.

The app, with large data storage for high volume testing, meets all your PAT testing needs. Take a picture and add it to the product register, scan a bar or QR code, and add your own logo to a printed label all in a matter of seconds. It will even produce a professional PDF report ready for email or print!

Alongside the SMARTPAT you can see the true power of the markets most efficient testing solution. Control and run the tester from the app and have the results appear straight onto your device in a matter of seconds!

The KEWPAT app can even control our KEW80L Bluetooth label printer allowing you to instantly print pass/fail labels with a number of bespoke designs including bar and QR code labels for even faster retesting with the app.

If you experience the KEWPAT app (using Apple iOS) displaying the green Wi-Fi connection symbol (see image 1) but does not actually communicate with your SMARTPAT the likely cause is an update of your device’s firmware made a change in the permissions for the app. This may not be initially obvious.

The solution is to go to your phone / tablet’s settings, scroll down to KewPat. Turn all permissions off and then on again. This should solve the communication issue.

Although rare it can come about after a software update and all the previous ‘permissions’ are not reinstated properly.

Step-by-step:

- Power on.

- Hold down the POWER key for five seconds, then release.

- INFORMATION shows.

- Press the POWER key to scroll through the INFORMATION list;

SPEED – NORMAL

DEEP – NORMAL

PAPER – LABEL

CMD – TSPL

SENSOR – THROUGH

LANGUAGE – ENG

FACTORY

The above are the correct settings. To change the settings, press the FEED key until you see the correct detail and then press POWER to set.

If the labels keep feeding through, press and hold the FEED key until either a series of numbers appears (older model) or you can hear a “ding” (latest model) and this will reset the label feed.

Please note. Always keep the ceramic contacts free of debris/adhesive

Maintaining your KEW-80L Bluetooth Direct Thermal Label Printer (Cleaning the Print Head)

If you own a KEW80L Bluetooth Label Printer with a Serial Number starting 221008 or higher, we recommend that you use the Larger 25mm Core Rolls which have around 275 labels. At the time of writing (21st Feb 2023) these currently have a Yellow Backing Paper, but this may change in future batches.

The recommended labels for the KEW80L are made from Polypropylene which gives additional durability and increased print quality when compared to standard paper labels.

There is however a trade-off when using Polypropylene Labels and Direct Thermal Transfer technology which is used in the KEW-80L Printer. While it’s not all bad, it does require that regular cleaning of the Print Head is carried out, more on that below.

How does Direct Thermal Transfer Work?

Direct Thermal Transfer Printers do not require any form of ink, toner, wax or even a ribbon, printing is achieved by using heat applied to the Print Head, the magic happens via a chemical reaction on the label itself.

The Thermal Print Head has a matrix of very small dots, each of which can be heated individually at great speed. As the label passes over the Thermal Print Head, heat is transferred onto the Label which in turn reacts with a layer of paper which has been impregnated with dye. This is the chemical reaction mentioned above and in turn produces the final image on the label.

Getting the optimum print quality is a fine balance between label stock, heat, the speed in which the label passes over the print head and software.

In order to produce an image, the Label must come in contact with the print head and therein lies one of the trade-offs of using what is in effect a plastic coated label.

Residue on the Print Head

Over time the Print Head will accumulate residue from the Polypropylene Labels during the heat transfer process. This can also be compounded by the label adhesive (between the label and backing paper) also becoming heated up and seeping from the edges during heavy use in quick succession.

The build up of this sticky residue on the Print Head can be gradual, but increase rapidly if not removed. The amount and speed in which it builds up can vary between Label Stock (individual Rolls or batches) and possibly environmental excesses such as temperature.

If residue is left to build up you will normally experience Labels Sticking, Mechanical Grinding or a different tone in the Motor as it works harder to feed the labels through. Labels may also become miss-aligned and general print quality will be degraded.

While we do carry out high intensity testing on various printers from time to time, we don’t use these printers on a regular daily basis, so we are unable to offer any specific advice on how often you should clean the head, however I would certainly recommend every 3 rolls to begin with and take it from there.

Cleaning the Print Head

The print head is the Black plate just below the serrated cutters as you open the lid. It is attached to a metal plate which is spring loaded.

It is important that we clear any residue before it has the chance to impact further on Print Quality and additional stress on the hardware and to do this I personally use small pre-soaked Acetone wipes which you will find in the beauty industry for removing Nail Gel Coat or Nail Varnish etc, however I have also used liquid nail varnish remover out of the bottle with a suitable cloth.

Have you nulled/zeroed your test lead?

You must null the test meter before carrying out this test.

Note. Both the red iec lead and the black earth bond lead supplied with Kewtech PAT testers have the same value. The test meter will remember the NULL and will also show this on the screen.

The dangers and incidences of a broken PEN conductor on the network’s supply have only recently been fully recognised. There is industry advice now that part of your safe isolation procedure should include a current test at the MET on the main earth bonding conductors to check that no current is flowing in components that could be common to other buildings.

This can be carried out with a KT200 or KEW2200 clamp meter both with 0.01A resolution. Or, for a full ‘safe isolation/everyday’ electrical tool the KT5 which offers non-contact, single pole and traditional two-pole voltage testing as well as a current measuring open jaw providing all the functions for proving dead in one instrument.

For those instruments that have an auto null facility for taking into account the resistance value of the test leads and which is remembered even when the instrument is switched off, the auto null memory needs to be cleared and reset from time to time. The Kewtech KT65DL and KT66DL procedure is below.

If adjacent to the F1 button NULL √ is shown remove this value:

Switch on the instrument.

Switch to continuity without the leads connected.

Press the test button and lockdown by turning it clockwise, >1999 is displayed.

Press the F1 button – NULL OFF should now be displayed.

Unlock the test button.

This has now cleared the memory.

Now refresh the test lead null.

Plug the test leads into L (brown) and PE (green).

Press and lock down the test button.

Short the tips together.

Press the F1 button and NULL √ should be displayed.

Unlock the test button.

YES!

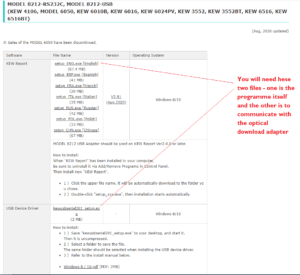

Customers without a CD drive can download the KEW REPORT software here straight to your computer.

A little known fact is that if a KEWTECH clamp meter has a MAX/MIN feature then the auto-sleep function is switched off when the MAX/MIN feature is selected. This means that you can leave the clamp measuring for a couple of days and when you come back to it, you will be able to recall the maximum current. This could perhaps save you having to hire a power quality analyser.

This is a question that we often get asked. The answer is a very positive YES for wherever 4 mm connectors are used, which is the vast majority of cases.

Many people buy our leads as first choice replacements. Our test leads go through a rigorous G7 test criteria including for pull out force, twisting/bending cycles and temperature. The items that are not universal are the probes which include the remote test button as comes with MFTs, as these connections are unique to each manufacturer.

There is much debate on how EV supply equipment should be tested. Some say that it is installed equipment and therefore the installation testing needs only to be done up to the equipment. We take the view that the installation including the EV charger should be tested. This is because the EV charger will, in the vast majority of cases, be located outside the equipotential area of a building and therefore has significant additional risks.

All our testers are capable of testing the loop and type A RCDs. Only the KT66DL is capable of testing Type B RCDs and 6 mA RDC-DDs both for individual time, tripping level as well as within auto sequences.

The equipment and the guidance for the installation of EV charging units are likely to develop over a long time. If you are intending to install EV charging units and are due for a new MFT, we strongly recommend you look at the KT66DL especially as it has features anticipating the future tightening up of the testing requirements for EV charging equipment.

Possible number of tests with fresh batteries.

CONTINUITY : Approx. 2000 times min. at load 1Ω

INSULATION RESISTANCE : Approx. 1500 times min. at load 1MΩ (1000V)

LOOP : Approx. 3000 times min. (ATT L-PE 3W)

RCD : Approx. 3500 times min. (G-AC X1 30mA)

EARTH : Approx. 3000 times min. at load 10Ω

VOLTS/PHASE ROTATION : Approx. 40h

Legionella is a bacteria found naturally in freshwater environments posing little threat to people. However, the bacteria have been found in industrial cooling systems, cooling towers and air conditioning among other installations which can result in a person developing the potentially fatal Legionnaires disease. In fact, around 500 people in the UK per year are affected by the disease

The bacteria multiply where temperatures are between 20°C and 45°C, however the bacteria lay dormant below 20°C and cannot survive above 60°C. That is why it is vitally important we check our water systems to guard against potential environments where Legionella can develop.

The L8 Legionella Testing kit is a dedicated temperature measuring kit for testing water systems to ensure that the conditions for Legionella bacteria growth does not exist.